Anodising

AMS’ anodising service offers the highest standards of quality, and aesthetics. Certified by Qualanod, our anodising process adheres to industry-leading standards, offering a diverse range of finishes, including Silver, Champagne, Light Bronze, Medium Bronze, Dark Bronze, and Black.

SAT s.r.l. of Italy led the installation and commissioning of our anodising plant, operational since May 2022. This state-of-the-art facility enables AMS to create anodised colours within aluminium profiles, sheets, or folded panels in our 7.2m x 2m process tanks. The computer-controlled operation guarantees efficiency, delivering consistent results. Automated cranes navigate the product through the production line, ensuring precision at every stage.

Certified by Qualanod in February 2023, our anodising plant adheres to rigorous industry standards, a testament to our commitment to quality. The Qualanod certification, a prerequisite for many architectural firms, attests to our processes. In-house, our dedicated laboratory maintains chemical compositions within tight tolerances, and our team of quality technicians conduct regular inspections and tests, upholding our commitment to meeting and exceeding Qualanod specifications.

- Qualanod certified

- Anodising creates a protective oxide layer on the surface of aluminium, enhancing its resistance to corrosion. This makes anodised aluminium suitable for outdoor and marine applications.

- The anodised layer is integral to the aluminium surface, making it more durable and resistant to wear and tear.

- Anodised surfaces are relatively easy to maintain.

- Anodising provides a natural and rich metallic look, enhancing the aesthetic appeal of aluminium surfaces.

- Rapid turnaround of anodised material

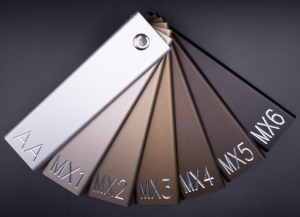

AA – Silver/Natural

MX1 – Champagne

MX2 – Light Bronze

MX3 – Medium Light Bronze

MX4 – Medium Dark Bronze

MX5 – Dark Bronze

MX6 – Black

AMS see the many positive benefits in contributing to corportate and social responsibility. Our company is built on the premise of being responsibe through the supply of aluminium products which is 100% recyclable.